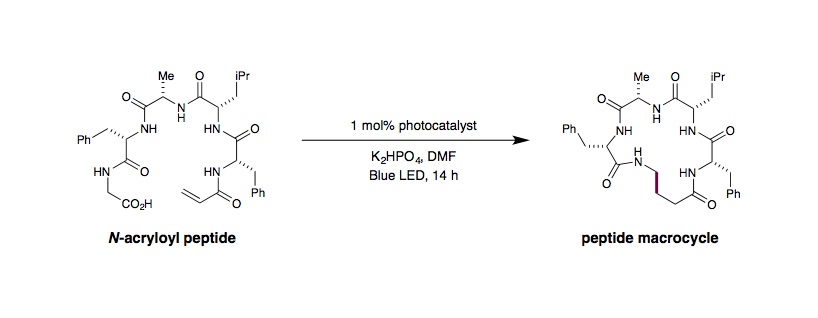

Decarboxylative Peptide Macrocyclization

S. J. McCarver, J. X. Qiao, J. Carpenter, R. M. Borzilleri, M. A. Poss, M. D. Eastgate, M. Miller, D. W. C. MacMillan

Light source:

Kessil Blue LED lamp. 2 lamps per reaction.

General procedure:

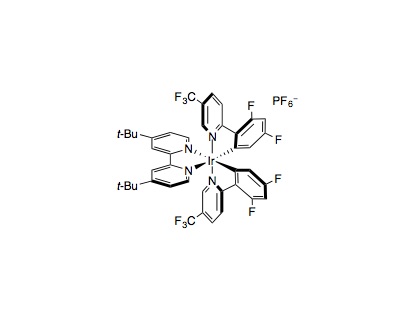

To a dry 8 mL vial with Teflon septum equipped with a stir bar was added Ir[dF(CF3)ppy]2(dtbbpy)PF6 (1.3 mg, 1.2 mmol, 0.12 equiv.), peptide (10.0 mmol, 1.0 equiv.), K2HPO4 (3.5 mg, 20.0 mmol, 2.0 equiv.), and DMF (2.5 mM, 4 mL). The vial was capped and the reaction mixture was degassed by sparging with N2 while stirring at 800 RPM for 20 min before sealing the vial with Parafilm. The reaction was stirred at 800 RPM and irradiated with 2 34 W blue LED lamp (one on each side of reaction vessel) with fan cooling to keep at room temperature until complete consumption of the starting material. Almost all reactions are complete within 14 hours, though reaction times as short as 6 hours can be observed. The reaction was centrifuged and subjected to RP-HPLC analysis for yield determination. For purification, samples were centrifuged and decanted to remove all heterogeneous material and then purified using preparative HPLC. Particularly clean and high yielding reactions (>80%) can be purified using C18 solid phase extraction cartridges. The sample is loaded onto the resin, washed with H2O, and then eluted with with an appropriate MeCN/H2O mixture (<50% MeCN allows for separation of the product from the photocatalyst).

Tips and tricks:

- K2HPO4 is universally the most effective base for the reaction, but KOH and KHCO3 provide comparable yields. For a homogeneous reaction DBU (0.5 equivalents) will provide the product but in diminished yield.

- The reaction will tolerate the addition of water up to 170 equivalents (3 mL for a 10 mmol reaction) without any change in yield, and when performing the reaction on small scale it is convenient to add the inorganic base as a stock solution in water.

- For low yielding reactions, further dilution and increased photocatalyst loading are typically effective to increase efficiency. For several substrates, addition of 10 mol% 2,4,6-triisopropylbenzenethiol led to increased efficiency and reaction rate.